Why Do Safety Pins Really Have Those Tiny Holes?

Safety pins probably have more uses that you can count. Traditionally, they are used to fasten pieces of clothing together, but they can be used for survival purposes, in first aid, and as part of fashion — such as clothing decoration and accessories. They can also be used for simple and easy science projects for kids such as a magnetism transfer experiment or making a windmill out of cardboard paper. While you might appreciate the various ways that safety pins enhance your life, you may not realize that the holes in them are an integral part of the design and function.

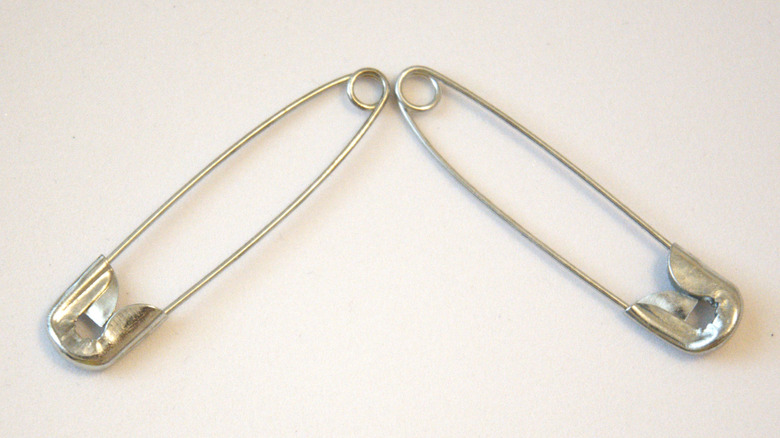

Larry Schwartz, the owner and CEO of Wholesale Safety Pins — a business entirely built around making these handy tools — gave Reader's Digest the inside scoop. There are two holes in these devices: one where the sharp end of the pin goes into a clasp or guard, and another at the bottom where the metal wraps around into a coil or spring. He explains that the purpose of the bottom hole is to maintain spring tension so that the pinhead remains in the guard. Without that coil hole tension, the pinhead would too easily move out of place if bumped and potentially cause an injury.

The clasp hole is just as important, though. It allows for the tip of the pin to more easily slip into and out of the guard, putting the "safe" in safety pin.

How the simple design of a safety pin works

Now that you know why safety pins have holes in them, how does such a simple design actually work? As mentioned, the hole at the bottom of the tool is integral to the coil's functionality, using mechanical principles like elasticity and tension to work.

Patented by inventor Walter Hunt in 1849 while playing with and twisting a piece of wire, this modern spring mechanism is now created by machines. They grab one end of the cut, high-carbon steel wire and tightly wrap it around a small mandrel. The coil creates the tension that allows the sharpened end of the safety pin to snap into the guard at the top and stay put until you apply enough force to open it. At the same time, that tension prevents the pin from overextending (or opening) beyond a certain point, which is also why you can unclasp and reclasp the device over and over again.

Hunt sold his safety pin patent to W.R. Grace and Company for $400. However, the design was such an improvement that the sale price was only a tiny fraction of the profits earned from the market.

Ancient safety pins differed but still had holes

The modern safety pin designed by Walter Hunt has remained largely unchanged since the 1850s, however, how does this modern design differ from the pins used by ancient civilizations? Few people know that the existence of the safety pin is steeped in ancient history, and while it's not one of the many discoveries to baffle archeologists, it has been the subject of archeological research.

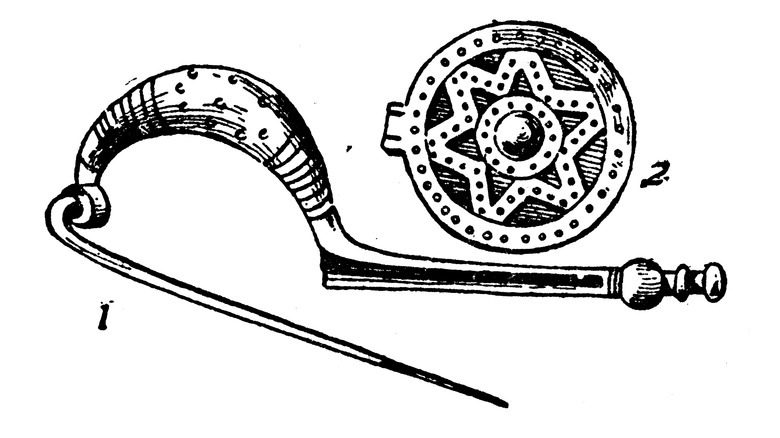

Termed "fibulae" in Latin, safety pins were initially invented in Europe during the Bronze Age. The exact location is still debated, but there were two basic forms. Commonly found in Northern Europe, the two-pin fibulae consisted of two pins that were originally straight. One pin was bowed with a hole at one end and a catch (or hook) at the other. The butt of the second pin fit through the hole of the first, while its tip rested in the hook of the first pin. With the two-pin fibulae, both pins were moveable but had no spring loop.

Commonly found in central Europe, Greece, and Italy, the single-pin fibulae are the most similar to modern safety pins. They consisted of a once straight pin that was bent into a spring loop in the middle. While one end was sharp, the other was bent into a hook to hold the sharp end. Modern safety pins still have a similar spring loop in the center, but they now have a better guard to protect users from pinpricks.